PULSECOOLING

TECHNOLOGY

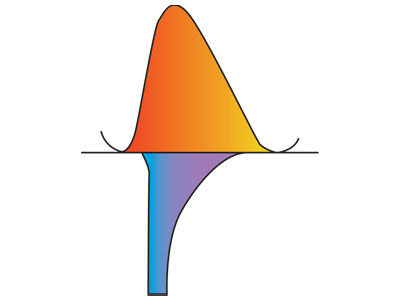

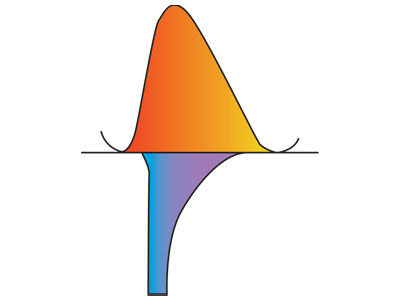

To obtain the highest performance and meet today's expectations, PulseCooling Technology is used to precisely meet the heating and cooling requirements of each molding cycle.

SEE HOW IT WORKSPulseCooling senses the mold surface temperature and applies a pulse of coolant at maximum flow rate directly from the chiller or cooling tower during each molding cycle for maximum heat removal. Each cooling pulse equals the excess heat from each molding cycle and compensates for cycle time, melt and ambient temperature and coolant pressure changes (flow).

To obtain the highest performance and meet today's expectations, PulseCooling Technology is used to precisely meet the heating and cooling requirements of each molding cycle.

SEE HOW IT WORKS