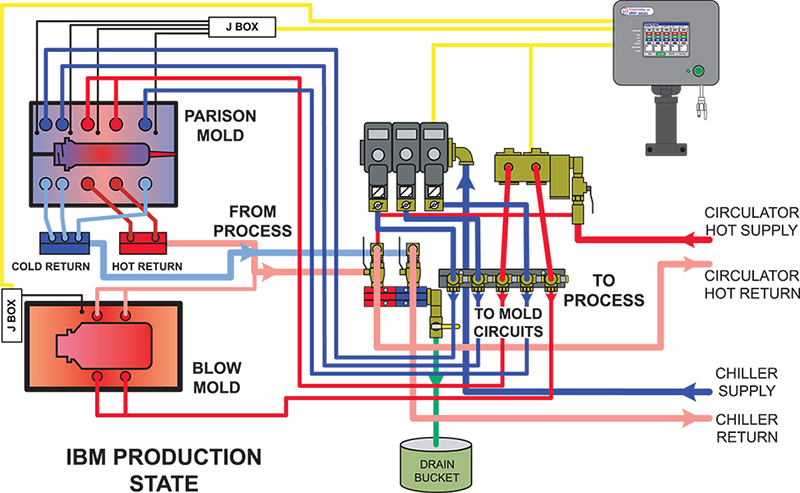

PULSECOOLING FOR INJECTION BLOW MOLDING

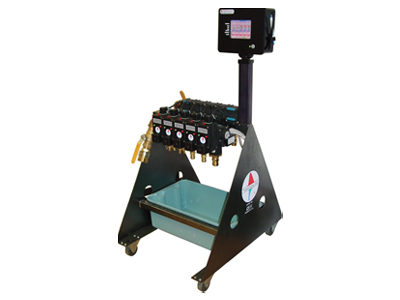

MODEL: PC5-IBM

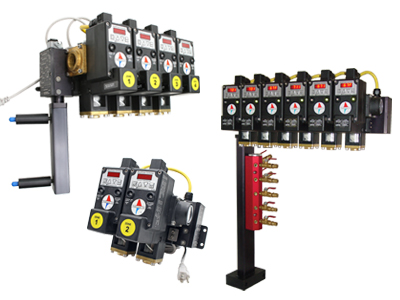

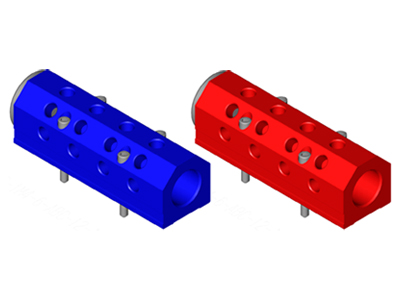

Touchscreen controller with 3 zones cooling and 2 zones heating up to 300 ˚F. Used in molding processes where a wide range of surface temperatures need to be critically maintained and controlled, typically used in Injection Blow Molding.Application: When mold sections require heating and cooling. This allows maximum temperature different within a mold.

Materials: Blow Molding Resins, Polyethylene, Polypropylene.

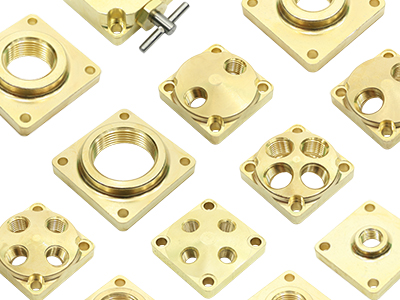

For custom assemblies, contact factory.