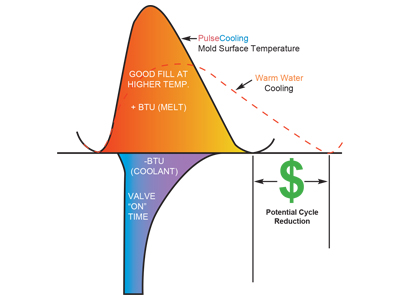

PRECISION PULSECOOLING: MAXIMIZING EFFICIENCY IN MOLD TEMPERATRURE CONTROL

To obtain the highest performance and meet today's expectations, PulseCooling technology is used to

precisely meet the heating and cooling requirements of each molding cycle.

Conventional Cooling verses PulseCooling Techology